Finnish coating technology specialist Picodeon Ltd has developed its ColdAb ultra-short pulsed laser deposition technology (US PLD) for use in the application of gold and platinum thin films, enabling thinner films and the reduction of precious metal costs.

Precious metals like gold and platinum are finding more and more industrial applications in memory storage, energy harvesting, energy storage and microelectromechanical systems (MEMS) applications. Traditional production methods for thin gold films include sputtering, evaporation and chemical vapour deposition, all of which have limitations either in quality, production effiency or industrial scalability.

Picodeon’s Coldab US PLD process produces thin films, down to nano-scale, with excellent quality at production rates exceeding, for example, sputtering technology.

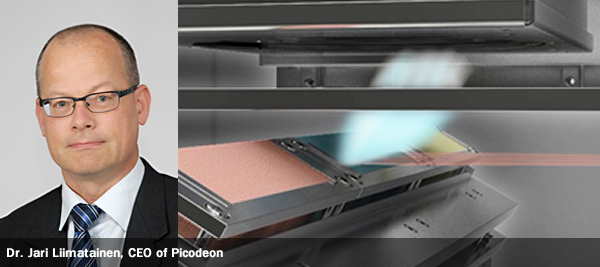

“Due to the high standard of film quality produced by Picodeon Coldab process, film thickness can be reduced by as much as 40-50 percent, cutting actual production costs,” said Picodeon CEO Dr. Jari Liimatainen. “Furthermore, the material yield from target to coating is excellent, typically 85-90 percent, giving additional cost savings in precious materials.”

Picodeon’s US PLD deposition is a cold ablation technology which works across a vast range of coating materials and substrates. By adjusting processing parameters, the structure and properties of the coating can be tailored to the requirements of the application, even for nanostructure-scale surface coatings. The US PLD technology delivers very high coating integrity without pinholes, giving improved thin film reliability.

“Picodeon recently delivered a development project related to sensors. We used ColdAb® Series2 R&D equipment to coat thin, less than 100 nanometer films, on silicon. Adhesion was achieved without any adhesive layers, and analytics showed a higher RAMAN intensity compared to standard Au coatings. This was exactly what we were looking for,” said Vice President of Sales, Mr. Marko Mylläri.

In addition to precious metal, Picodeon’s Coldab process enables the deposition of high hardness compounds such as diamond-like carbon compounds, carbon nitrides, and carbon nitride composites containing polytetrafluoroethylene (PTFE), boron nitride (BN) or boron carbide (BC) as well as a wide range of other borides, oxides and precious metal thin films.

The high production rates and excellent coating qualities of Picodeon Coldab US PLD technology open new possibilities and applications for pulsed laser deposition coatings. In selected areas it may even enable the development of exclusive coating methods.